Heavy Duty Ductile Iron Manhole Cover

High Load Capacity – Designed for heavy-duty roads, complies with EN124 standards.

Durable & Long-Lasting – Made from high-strength ductile iron, ensuring extended service life.

Waterproof & Sealed Design – Prevents water infiltration, protecting underground utilities.

Anti-Slip Surface – Textured design enhances traction for vehicles and pedestrians.

Corrosion & Rust Resistant – Special coating ensures performance in harsh environments.

Customizable Options – Available in various sizes, shapes, and with logo engraving.

Product descriptions from the supplier

Product Description

Ductile iron manhole cover is made from spheroidal graphite cast iron by machining hand moulding, solid top, recessed,double triangular, single seal or double seal, square or rectangular or round,with or without hinge. Very good quality, smooth and free from sand holes, blow holes, distortion or any other defects. Loading capacity is 40 tons. The normal coating is black bitumen 30 microns thickness, also can make the epoxy coating according to the customer’s demand.

Clear opening size is as below:

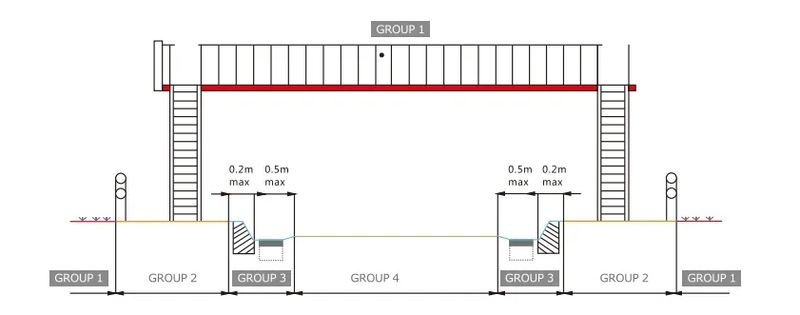

- GROUP 1: (class A 15 minimum) Test 1.5 metric ton

Areas which can only be use by pedestrians and pedal cyclists.

- GROUP 2: (class B 125 minimum) Test 12.5 metric ton

Footways, pedestrian areas and comparable areas, car parks or car parking decks.

- GROUP 3: (class C 250 minimum) Test 25 metric ton

For gully tops installed in the area kerbside channels of roads which when measured from the kerb edge, extend a maximum of 0.5m

into the carriageway and a maximum of 0.2m into the footway.

- GROUP 4: (class D 400 minimum) Test 40 metric ton

Carriageway of roads (including pedestrian street), hard shoulders and parking areas, for all types of road vehicles.

- GROUP 5: (class E 600 minimum) Test 60 metric ton

Areas imposing particularly high wheel loads, e.g. docks, aircraft pavements.

- GROUP 6: (class F 900 minimum) Test 90 metric ton

Areas imposing particularly high wheel loads, e.g. Aircraft pavements.

The standard specifies that the designer is responsible for making the appropriate choice of class and where there is any doubt

regarding the class to be used, a higher class should be selected.

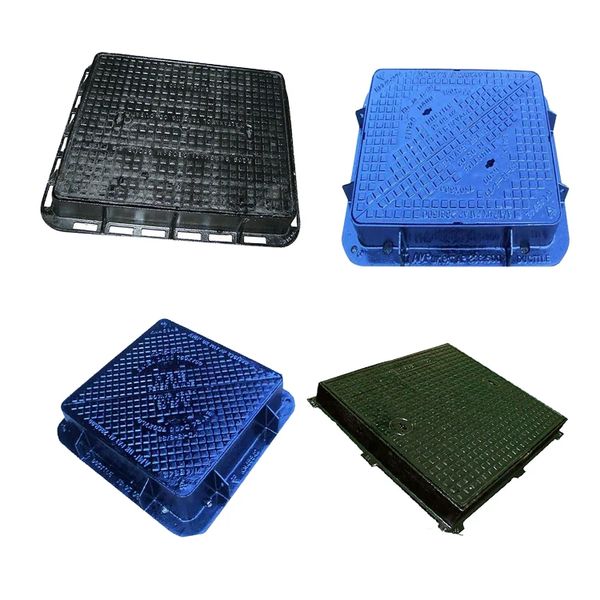

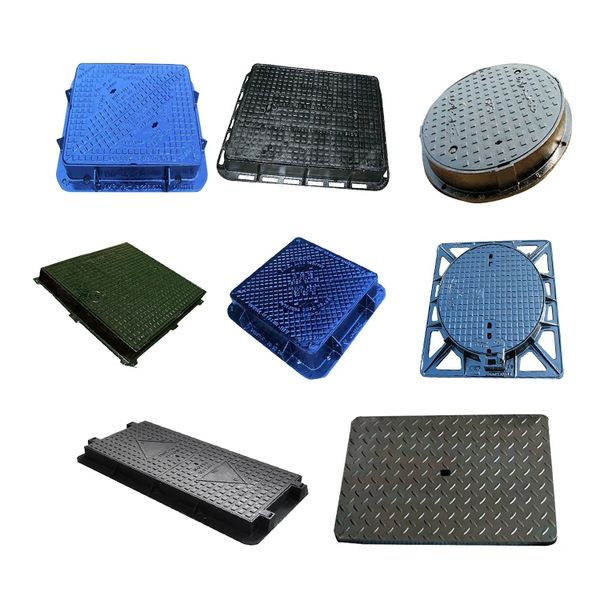

1) Solid Cover Series

* Ductile Iron

* Two Lifting Keyholes

* Cut-Corner Design (Regular corner covers are also available)

* Diamond raised top design

2) Double Sealed Series

* Ductile Iron

* Double Sealed

* 2 Lifting Key Holes

* Cut-Corner Design (Regular corner covers are also available)

Some types come with GRP sealing plate.

3) Double Triangular Series

* Ductile Iron

* Double Triangular

* Square Plate raised top design

* Special inscription or different identification is available

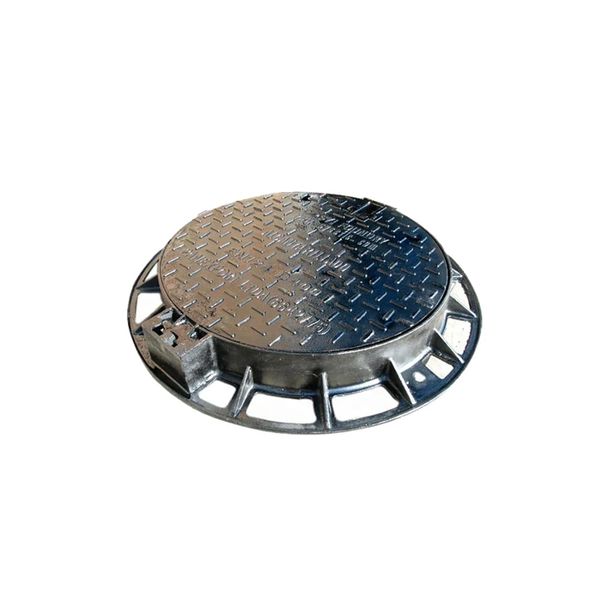

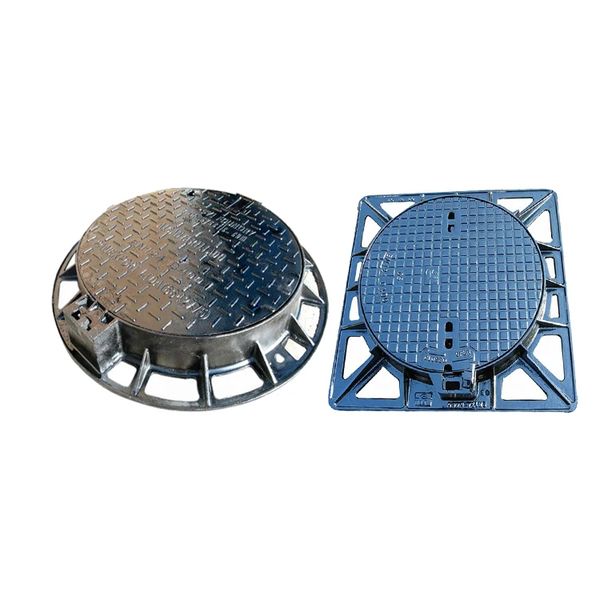

4) Round Cover Series

* Ductile Iron

* Double Triangular

* Square Plate raised top design

* Special inscription or different identification is available

Round frames, Square frames and Octagonal frames are available.

Some types come with GRP sealing plate.

Company Profile

We are specialized in supplying all kinds of the casting and forging parts for about more 30 years.Design,develop,produce and deliver according to your drawings,samples or just an idea!

* provides technical process analysis, develops and manufactures different technology OEM castings and forgings integrating all the resources according to customers' requirements

* We starts its business from an OEM supplier since 1990's of machined & Non-machined castings and forgings in a variety of industries.

* We are both manufacturer and trading company, and breaks its limit of one factory

* we has 100 strategy partners in different technology production

* a specialized team including translators,engineers,inspectors,and customer service

* developed over 10000 products till now

* Any OEM enquiry will be set up a project,and will be treated as an emphasis in the group

* 30 years of independent development and design ability

* 30 senior engineers

* Auto CAD/Pro Engineer/Solid Works

* Dual control of Standard products and OEM products

Packing&Delivery