Bridge Drainage Pipe

Product Advantages:

1. High Strength and Durability

2. Excellent Corrosion Resistance

3. Efficient Drainage Performance

4. Temperature Resistance

5. Easy Installation and Maintenance

6. Environmentally Friendly Materials

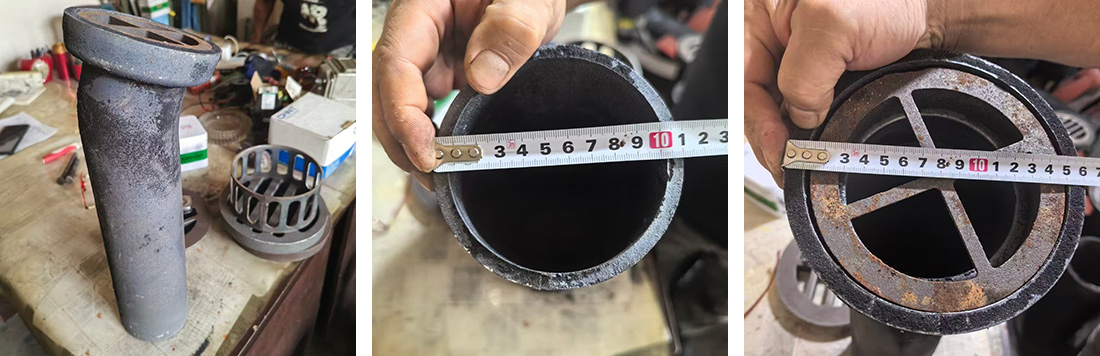

Bridge Drainage Pipe Details:

Below is a detailed description of the bridge drainage pipe, including its specifications, materials, performance, and other key information to help you understand its technical features and applications.

Product Description:

The bridge drainage pipe is made from high-strength, corrosion-resistant materials specifically designed for the drainage systems of bridges and related infrastructure. The smooth inner walls reduce water flow resistance, ensuring rapid drainage of rainwater and surface water, preventing accumulation on the bridge deck. The product also boasts excellent weather resistance, making it suitable for extreme climate conditions.

Product Parameters:

Product Name | Bridge Drainage Pipe |

Material | High-Density Polyethylene (HDPE), Steel, Cast Iron, PVC, etc. |

Size Specifications | Diameter:50mm-300mm, Length: Customizable |

Thickness | 2mm - 8mm (Customizable) |

Drainage Capacity | High-efficiency drainage with flow rates up to 2.5m/s |

Temperature Range | -40°C to 80°C (depending on material) |

Corrosion Resistance | Resistant to acids, alkalis, salts, and chemicals |

Pressure Resistance | Can withstand pressures up to 30MPa |

Installation Method | Quick-connect or threaded, easy to install and maintain |

Applicable Environment | Highway bridges, railway bridges, urban elevated roads, etc. |

Service Life | Over 30 years |

Color | Black, grey, or custom colors |

Standards | Compliant with GB/T 13663, ISO 4427, and other standards |

Features | Temperature,resistance,highstrength, corrosion-resistant,eco-friendlymaterials, self-cleaning feature |

Applications | Bridge drainage, culvert drainage, highway drainage, etc. |

Customization | Custom sizes and designs available based on project requirements |

Installation and Maintenance:

The bridge drainage pipe features easy installation methods, such as quick-connect systems, which shorten construction time and reduce costs. The product also has a self-cleaning function, minimizing the need for regular cleaning and maintenance while ensuring long-term efficient operation.

Bridge drainage pipes play a crucial role in the drainage system of bridges. Their primary function is to remove water from the bridge deck, preventing water accumulation that could damage the bridge structure. To ensure the long-term use and safety of bridges, high-quality drainage pipes offer the following key advantages:

1. High Strength and Durability

Bridge drainage pipes are typically made from high-strength materials such as high-density polyethylene (HDPE), steel, or cast iron. These materials provide excellent pressure resistance and impact resistance, allowing the pipes to withstand the effects of traffic loads without deformation or damage, ensuring long-term system stability.

2. Excellent Corrosion Resistance

Since drainage pipes are exposed to environmental elements such as rain, moisture, and chemical substances (e.g., de-icing agents), high-quality pipes are made from materials with superior anti-corrosion properties. This prevents rusting and extends the service life of the pipes, reducing maintenance costs.

3. Efficient Drainage Performance

The design of drainage pipes focuses on maximizing water flow efficiency. With smooth inner walls and minimal resistance, the pipes ensure that rainwater is quickly drained from the bridge surface, preventing water accumulation, reducing the risk of slippery surfaces, and enhancing driving safety.

4. Temperature Resistance

Bridge drainage pipes are exposed to extreme weather conditions, such as cold winters and hot summers. High-performance drainage pipes are designed to maintain their structural integrity across a wide temperature range. They resist cracking in low temperatures and softening in high temperatures, making them suitable for diverse climates.

5. Easy Installation and Maintenance

Many drainage pipes are designed with modular and standardized components, allowing for quick installation and replacement, which reduces labor costs and construction complexity. Additionally, self-cleaning features or simplified designs minimize blockages and the need for frequent cleaning, lowering maintenance requirements.

6. Environmentally Friendly Materials

Many high-quality drainage pipes are made from environmentally friendly materials, free from harmful substances. They align with green construction initiatives and are safe for both the environment and bridge construction.

For further customization or detailed information, please feel free to contact us.