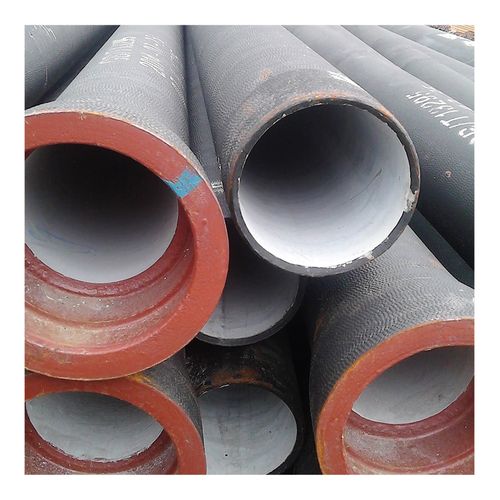

DN 150 Ductile Iron Pipes

Exceptional Strength and Toughness: Ductile iron pipes have high tensile strength and excellent toughness, able to withstand high-pressure environments, making them suitable for various pipeline projects.

Outstanding Corrosion Resistance: The specially treated surface performs excellently in various corrosive environments, extending the lifespan of the pipes and reducing maintenance costs.

High Wear Resistance: They perform exceptionally well under friction and wear conditions, ensuring long-term stability and reducing the frequency of replacements.

Flexible Connection Options: Available with flange connections, socket connections, and more, allowing for quick and easy installation, minimizing construction time.

Excellent Sealing Performance: Effectively prevents leakage, enhancing water resource utilization and ensuring efficient system operation.

Ductile Iron Pipes Product Details

Overview

Ductile iron pipes are engineered for superior strength, durability, and versatility in various applications. These pipes are ideal for water supply, sewage systems, and industrial use. Their unique properties make them a reliable choice for infrastructure projects.

Key Features:

Material Composition: Made from high-quality ductile iron, ensuring robust performance.

Surface Treatment: Special coatings enhance corrosion resistance, extending service life.

Connection Types: Available in various connection options for flexible installation.

Sizes Available: A wide range of diameters to meet diverse project requirements.

Technical Specifications:

| Specification | Details |

|---|---|

| Material | Ductile Iron (ISO 1083) |

| Standard | ANSI/AWWA C151/A21.51 |

| Diameter Range | 3" to 64" (75mm to 1600mm) |

| Pressure Rating | Up to 350 psi (24 bar) |

| Length | Standard lengths of 18', 20', 21' |

| Weight | Varies by diameter; typically 1.5 to 3 tons per pipe |

| Coating Options | Cement mortar, epoxy, bitumen, or customized |

| Joinery Type | Flanged, socket, or push-on joint |

Advantages of Ductile Iron Pipes:

High Strength: Ductile iron pipes offer significantly higher strength compared to traditional cast iron, making them ideal for high-pressure applications.

Corrosion Resistance: The advanced coatings used provide excellent protection against rust and corrosion, particularly in aggressive environments.

Longevity: With proper installation and maintenance, ductile iron pipes can last for over 100 years, minimizing replacement costs.

Impact Resistance: Their design allows them to withstand impact and external pressure, ensuring reliability in various conditions.

Cost-Effective: While initial costs may be higher, the reduced maintenance and longer lifespan lead to lower overall costs.

Applications:

Water Supply Systems: Ideal for municipal and industrial water supply.

Sewage and Wastewater: Suitable for sewage systems, ensuring reliable transportation of waste.

Industrial Use: Effective in various industrial applications, including chemical processing.

Ordering Information:

For quotes and orders, please contact us with the following details:

Required diameter and length

Preferred coating options

Quantity needed

Delivery timeline

Conclusion

Ductile iron pipes are a premium choice for any pipeline project, combining strength, durability, and flexibility. By choosing our pipes, you invest in a reliable and long-lasting solution for your infrastructure needs.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible